CAM

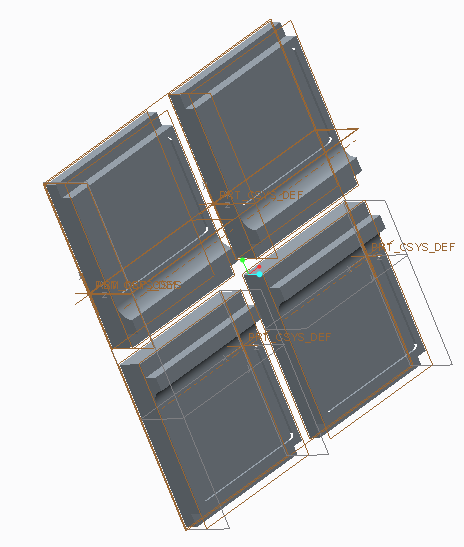

Today I formatted my CREO drawings to be compatible with the CNC machines. The outer former has been grouped together to form one cutting piece as oppose to being cut singularly. This will reduce set up time, which saves money and reduces carbon emissions.

The material I've chosen to use is model board. This will ensure a smooth finish to the surface of the formers. Some light sanding may be required prior to use. Sealant or wrap to also reduce chemical attack from the concrete.

Below is the feature which will be attached to the mould. I'll need four of these pieces to complete the mould. Due to the 3D printer being costly, I've decided to 3D print one piece and make a silicone cast to duplicate the remainder.

The feature has been shelled (as seen below). This again reduces time, money and carbon emissions. Throughout this project I've been mindful of cost and energy efficiency.

No comments:

Post a Comment